Added Innovation

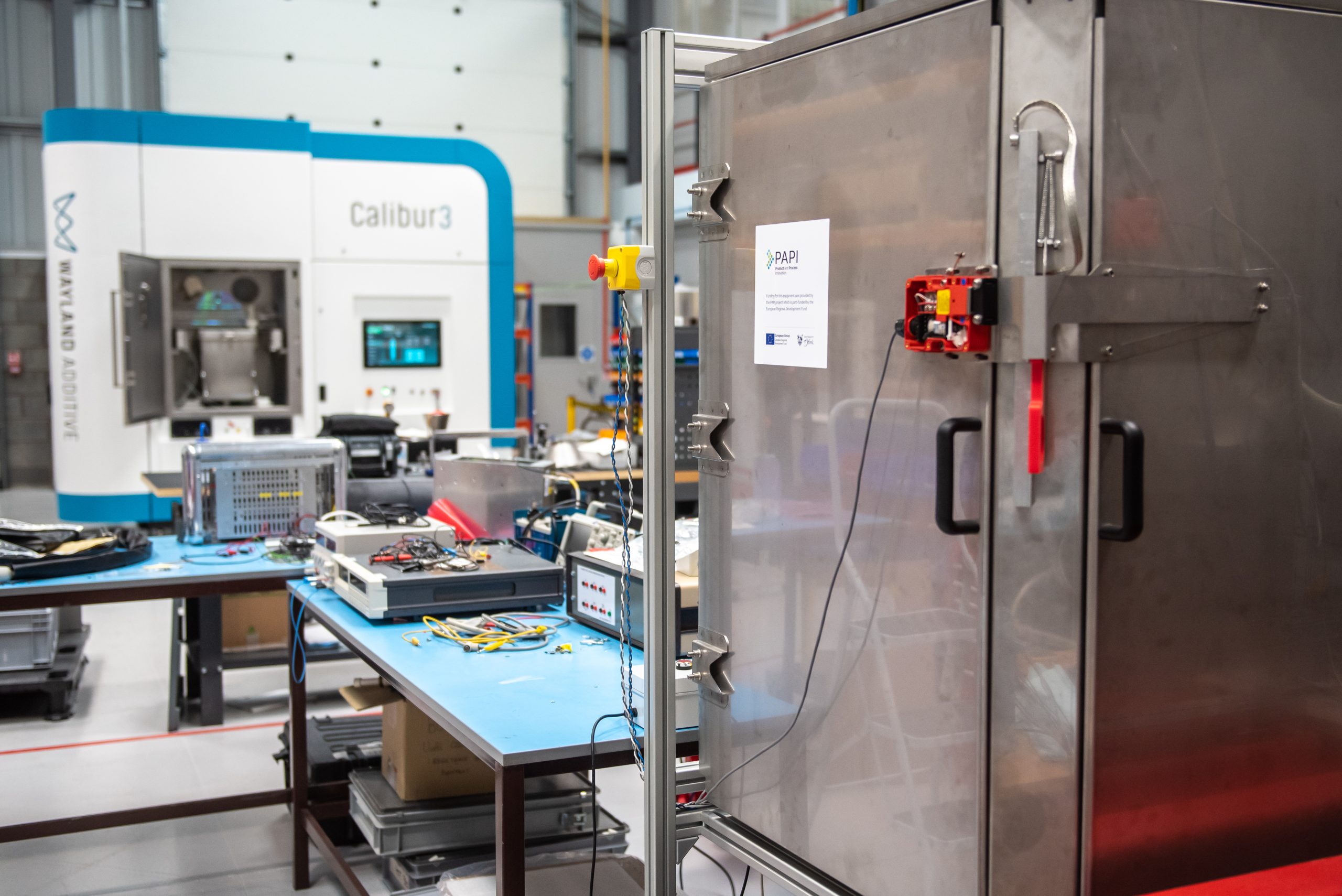

Wayland Additive create a new, innovative product with PAPI support

Wayland Additive, based in Huddersfield, is an innovative company with with a long-established reputation as industry leaders in electron beam (e-beam) manufacturing expertise. The company develop cutting edge additive manufacturing (AM) processes.

The company was born out of a high precision engineering team with experience in the use of e-beam technology in semiconductor manufacturing. They believed that its use in additive manufacturing could be improved. Thus, in 2015 a team of e-beam experts from the lithography world began to coalesce around solving the single most serious problem inherent in the e-beam AM process: the charging of the powder. Wayland created a solution to the problem with a stable and capable process.

Innovation

3D printing/AM are general terms encompassing a variety of systems used to create physical parts and models from digital data. AM typically uses layer-by-layer (additive) means of construction to build in extremely thin, cross-sectional layers. This allows for the manufacturing of complex and intricate shapes and surfaces, more simply than by conventional processes such as machining, casting, and forging. Typically, currently metal AM machines use a laser rather than an e-beam, but the resolution of the parts that can be manufactured is limited by this laser process.

Business growth

Wayland created a new-to-market, high-resolution e-beam machine, which produces parts much faster and with finer features than previous machines. The machine uses a high-powered e-beam to melt metallic powder, which is laid down in thin layers. This allows the manufacture of high-resolution free-form parts, which are especially valuable to the medical and aerospace sectors.

Wayland Additives were awarded a £17,280 PAPI grant to support the development of version 2 of the machine. This was used to purchase electron optical design modelling software, a high-voltage power supply, and a beam control unit.

The project created an innovative machine that was new to the market, and 7 new jobs within the business. This project also had significant, positive impacts on the local and regional economy.

Since the PAPI grant, our growth rate is phenomenal. We're now 42 people and we're looking to grow to 100 people in the not too distant future.