Duraweld Pivots For Success

Scarborough-based firm branches out into PPE production to meet NHS demand, with PAPI support

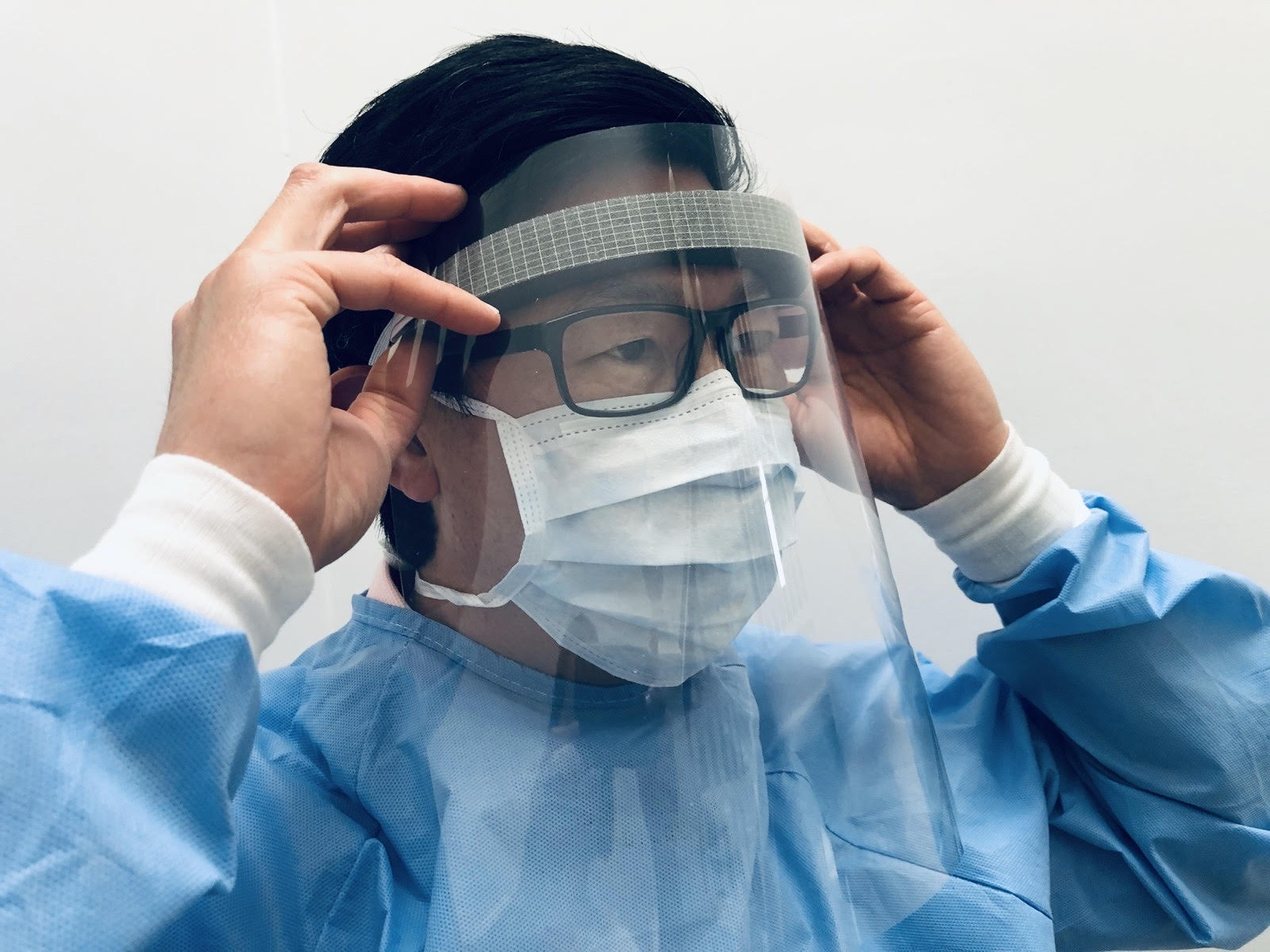

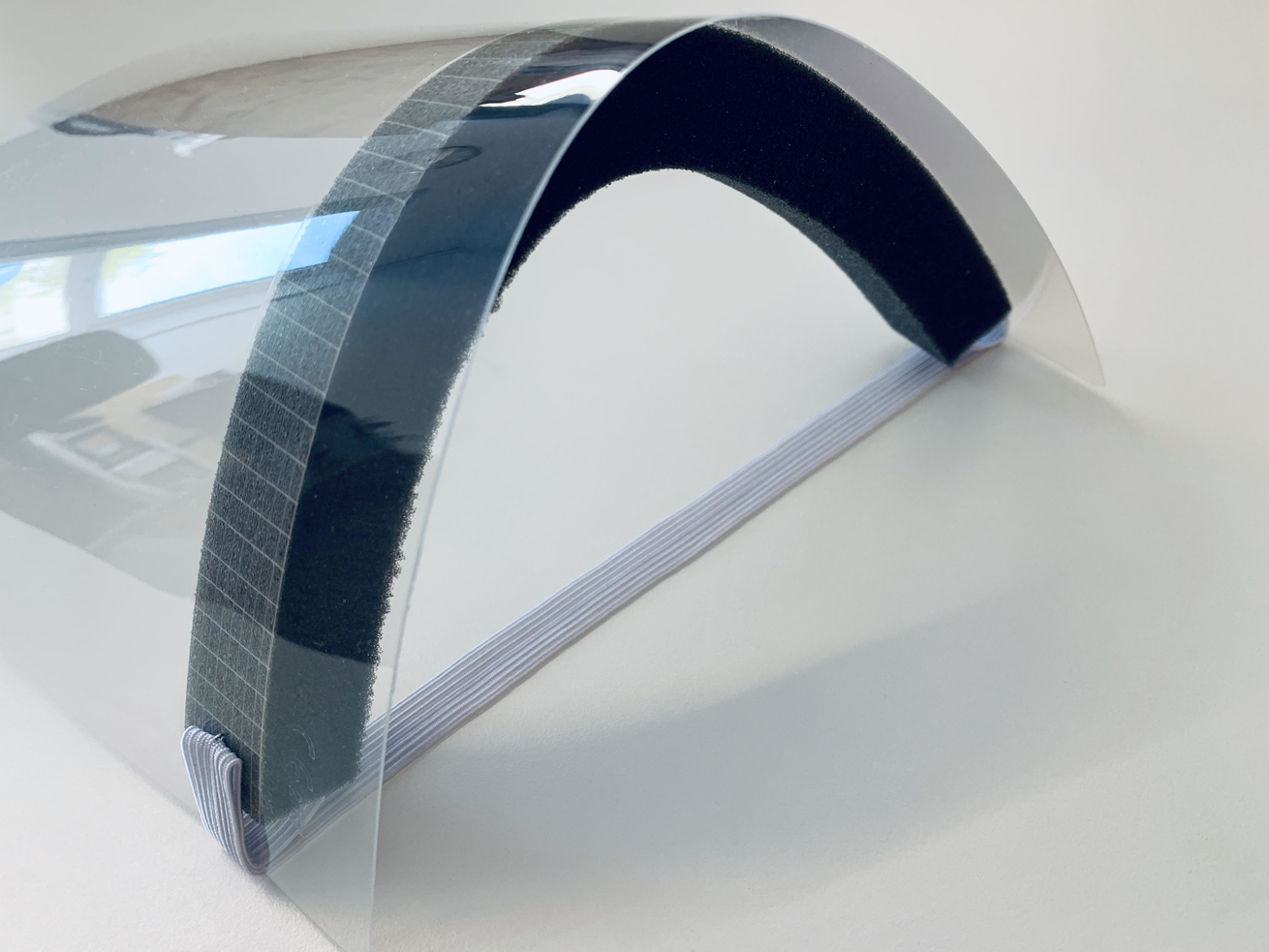

Duraweld usually manufacture stationary and packaging products including bespoke ring-binders and ID badges. Their customers include Aston Martin, Bentley, Costa and BT. When the UK lockdown was announced, they saw a reduced demand in their products and made the decision to apply their expertise in design of plastic products to develop a low-cost disposable, polypropylene visor.

Innovation

Following the outbreak of the COVID-19 pandemic in March 2020, the UK government had an immediate requirement for industry to increase manufacturing of personal protective equipment (PPE). Duraweld Ltd, based in Scarborough, sought to supply face visors to the NHS, but had limited automated processes.

A digital cutting machine was purchased, supported by a £20,000 grant from PAPI, and the company was able to increase production from an initial forecast of 10,000 visors per day to 28,000 per day. Duraweld are currently contracted to supply 5.2 million face visors to the NHS by December 2020, protecting front-line workers and patients across the country.

Supporting the NHS

Through the project, Duraweld have been able to secure the jobs of 27 employees, who were previously furloughed, and employ an additional 45 staff on an initial six month contract. After the government contract has been fulfilled, Duraweld will be able to use the new machinery to develop and manufacture a new range of products and enter new markets as the economy recovers.

[PAPI] have been fantastic to work with. At the height of the pandemic, when we were under pressure and working at a very fast pace, the help, support and flexibility was massively appreciated.